How Does DED Technology Work?

- quotes906

- Mar 28, 2025

- 2 min read

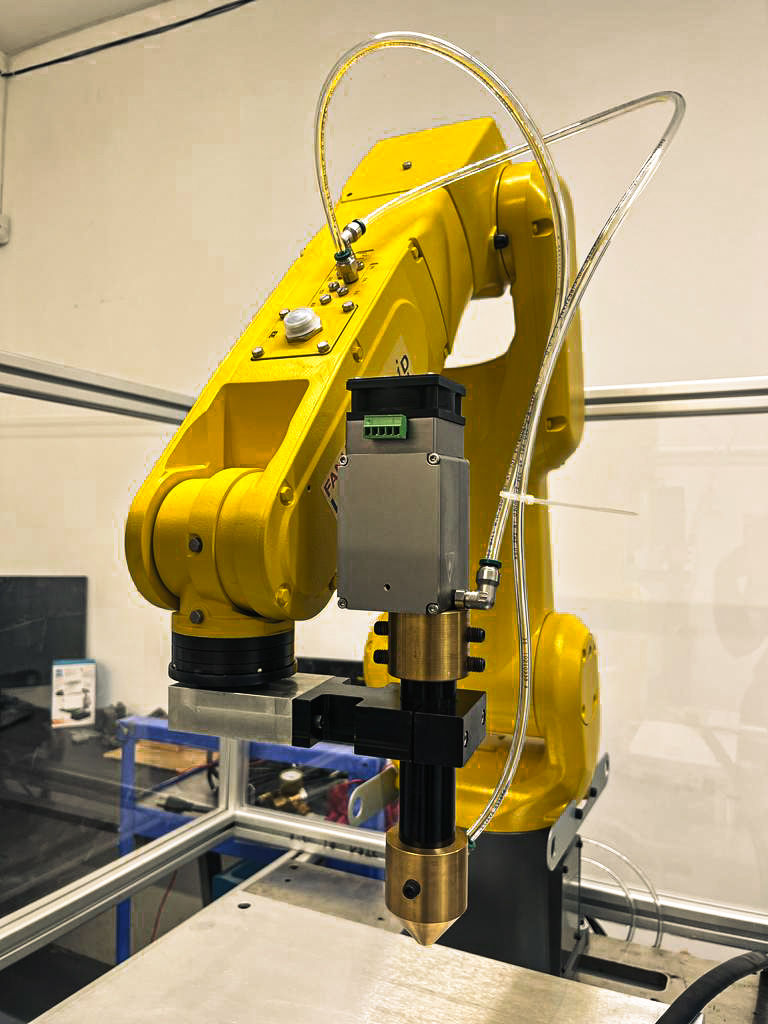

Additive manufacturing is revolutionizing the way we create and repair metal parts. Among these innovations, Directed Energy Deposition (DED) stands out for its precision and versatility. But how does it really work? Here’s a simple explanation.

What is DED Technology?

Imagine a 3D printer, but instead of plastic, it uses molten metal. DED is an additive manufacturing process that employs a concentrated energy source—such as a laser, electron beam, or plasma arc—to melt and deposit metallic material onto a surface. This allows for the creation of new parts from scratch, the repair of worn components, and the enhancement of existing metal structures.

Step by Step: How Does It Work?

The DED process may seem complex, but it follows four key steps:

Material Supply: Metallic material (in powder or wire form) is fed into a specialized nozzle.

Energy Fusion: Simultaneously, an intense heat source (laser, electron beam, or plasma arc) melts the material exactly at the point of contact.

Layer-by-Layer Deposition: As the molten metal solidifies, the part is gradually built up, layer by layer.

Multi-Axis Movement: The nozzle and energy source move in multiple directions, allowing for the creation of complex shapes and precise repairs.

What Is DED Used For?

DED is an incredibly useful technology across various industries, especially in aerospace, automotive, and manufacturing. Some of its most common applications include:

Repairing Metal Parts: Ideal for restoring damaged components without the need for a completely new part.

Reinforcing Structures: Additional material can be added to existing parts to enhance their strength.

Manufacturing Large Parts: Perfect for building large components that can later be refined through machining.

Why Is It So Important?

DED technology is changing how we work with metals. Its ability to repair and manufacture parts quickly and precisely makes it a key tool in many industries. Best of all, it continues to evolve, paving the way for new applications and improvements in the future.

What do you think about this technology? Let’s keep exploring the future of 3D printing together!

Comments